Shafts a and B Connect the Gear Box to the Wheel Assemblies of a Tractor, and Shaft C -chegg

A differential is a gear train with three bulldoze shafts that has the property that the rotational speed of one shaft is the boilerplate of the speeds of the others, or a fixed multiple of that average.

Functional clarification [edit]

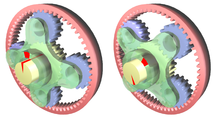

Input torque is applied to the ring gear (blueish), which turns the entire carrier (blue). The carrier is connected to both sunday gears (red and yellow) but through the planet gear (green). Torque is transmitted to the sun gears through the planet gear. The planet gear revolves around the axis of the carrier, driving the sun gears. If the resistance at both wheels is equal, the planet gear revolves without spinning about its own axis, and both wheels turn at the aforementioned charge per unit.

If the left sun gear (cherry-red) encounters resistance, the planet gear (green) spins likewise as revolving, allowing the left sun gear to ho-hum down, with an equal speeding upwards of the right dominicus gear (yellow).

The following description of a differential applies to a traditional rear-wheel-drive car or truck with an open or limited skid differential combined with a reduction gearset using bevel gears (these are not strictly necessary; see spur-gear differential):

Thus, for example, if the machine is making a turn to the right, the main ring gear may make ten total rotations. During that time, the left wheel will make more rotations because it has farther to travel, and the correct bike will make fewer rotations as it has less altitude to travel. The sun gears (which drive the axle one-half-shafts) will rotate at dissimilar speeds relative to the ring gear (i faster, one slower) by, say, ii full turns each (four full turns relative to each other), resulting in the left wheel making 12 rotations, and the right wheel making 8 rotations.

The rotation of the ring gear is always the boilerplate of the rotations of the side sun gears. This is why if the driven roadwheels are lifted clear of the ground with the engine off, and the drive shaft is held (say, leaving the transmission in gear preventing the ring gear from turning inside the differential), manually rotating one driven roadwheel causes the opposite roadwheel to rotate in the opposite direction by the same corporeality.

When the vehicle is traveling in a straight line there will be no differential motility of the planetary system of gears other than the minute movements necessary to recoup for slight differences in cycle bore, undulations in the route which make for a longer or shorter wheel path, etc.

Applications [edit]

ZF Differential. The drive shaft enters from the front and the driven axles run left and right.

In automobiles and other wheeled vehicles, the differential allows the outer drive bicycle to rotate faster than the inner drive wheel during a turn. This is necessary when the vehicle turns, making the wheel that is traveling around the outside of the turning bend curl farther and faster than the other. The average of the rotational speed of the two driving wheels equals the input rotational speed of the drive shaft. An increment in the speed of one bicycle is counterbalanced by a subtract in the speed of the other.

When used in this way, a differential couples the longitudinal input propeller shaft to the pinion, which in turn drives the transverse ring gear of the differential. This likewise usually works as reduction gearing. On rear wheel bulldoze vehicles the differential may connect to half-shafts inside an beam housing, or bulldoze shafts that connect to the rear driving wheels. Front cycle bulldoze vehicles tend to have the engine crankshaft and the gearbox shafts transverse, and with the pinion on the terminate of the counter-shaft of the gearbox and the differential enclosed in the same housing as the gearbox. There are individual bulldoze-shafts to each bicycle. A differential consists of one input (the drive shaft) and two outputs, which are connected to the ii drive wheels; however the rotations of the drive wheels are coupled to each other past their connection to the roadway. Nether normal conditions, with pocket-sized tyre slip, the ratio of the speeds of the two driving wheels is defined by the ratio of the radii of the paths around which the ii wheels are rolling, which in turn is determined by the track-width of the vehicle (the distance betwixt the driving wheels) and the radius of the plow.

Non-automotive uses of differentials include performing analog arithmetic. Two of the differential's iii shafts are fabricated to rotate through angles that correspond (are proportional to) two numbers, and the angle of the tertiary shaft'southward rotation represents the sum or departure of the two input numbers. The primeval known employ of a differential gear is in the Antikythera mechanism, circa eighty BCE, which used a differential gear to command a small sphere representing the moon from the difference between the sun and moon position pointers. The ball was painted black and white in hemispheres, and graphically showed the stage of the moon at a particular signal in fourth dimension.[1] An equation clock that used a differential for improver was made in 1720. In the 20th Century, large assemblies of many differentials were used every bit analog computers, computing, for example, the direction in which a gun should be aimed.[2]

History [edit]

There are many claims to the invention of the differential gear, but it is possible that it was known, at least in some places, in ancient times. Confirmed historical milestones of the differential include:

- 100 BCE–70 BCE: The Antikythera machinery has been dated to this catamenia. It was discovered in 1902 on a shipwreck by sponge divers, and mod research suggests that information technology used a differential gear to determine the angle between the ecliptic positions of the Sunday and Moon, and thus the phase of the Moon.[1] [3]

- c. 250 CE: Chinese engineer Ma Jun creates the first well-documented south-pointing chariot, a forerunner to the compass that uses differential gears to discern direction rather than a magnet.

- 1720: Joseph Williamson uses a differential gear in a clock.

- 1810: Rudolph Ackermann of Germany invents a 4-wheel steering system for carriages, which some later writers mistakenly report as a differential.

- 1827: modern automotive differential patented by watchmaker Onésiphore Pecqueur (1792–1852) of the Conservatoire National des Arts et Métiers in French republic for use on a steam railroad vehicle.[4] [5]

- 1832: Richard Roberts of England patents "gear of compensation", a differential for road locomotives.

- 1874: Aveling and Porter of Rochester, Kent list a crane locomotive in their catalogue fitted with their patent differential gear on the rear axle.[half dozen]

- 1876: James Starley of Coventry invents chain-drive differential for employ on bicycles; invention later used on automobiles past Karl Benz.

- 1897: first use of differential on an Australian steam auto past David Shearer.

- 1958: Vernon Gleasman patents the Torsen dual-drive differential, a blazon of express-slip differential that relies solely on the action of gearing, instead of a combination of clutches and gears.

Epicyclic differential [edit]

Epicyclic gearing is used here to apportion torque asymmetrically. The input shaft is the green hollow 1, the yellow is the low torque output, and the pink is the high torque output. The force applied in the xanthous and the pinkish gears is the same, but since the arm of the pink one is ii× to 3× as large, the torque volition exist 2× to 3× as high.

An epicyclic differential can utilise epicyclic gearing to divide and apportion torque asymmetrically betwixt the front and rear axles. An epicyclic differential is at the heart of the Toyota Prius automotive bulldoze train, where information technology interconnects the engine, motor-generators, and the drive wheels (which have a 2d differential for splitting torque as usual). Information technology has the reward of existence relatively compact along the length of its axis (that is, the sun gear shaft).

Epicyclic gears are also called planetary gears considering the axes of the planet gears revolve around the common axis of the dominicus and ring gears that they mesh with and roll between. In the image, the yellow shaft carries the lord's day gear which is almost hidden. The bluish gears are called planet gears and the pink gear is the ring gear or annulus.

Band gears are also used in starter motors.

Spur-gear differential [edit]

A spur gear differential constructed by engaging the planet gears of two co-axial epicyclic gear trains. The casing is the carrier for this planetary gear train.

A spur-gear differential has two equal-sized spur gears, one for each half-shaft, with a space between them. Instead of the Bevel gear, as well known as a miter gear, assembly (the "spider") at the centre of the differential, at that place is a rotating carrier on the same centrality as the 2 shafts. Torque from a prime mover or transmission, such as the bulldoze shaft of a car, rotates this carrier.

Mounted in this carrier are i or more than pairs of identical gears, more often than not longer than their diameters, and typically smaller than the spur gears on the individual half-shafts. Each pinion pair rotates freely on pins supported by the carrier. Furthermore, the pinion pairs are displaced axially, such that they mesh merely for the office of their length between the ii spur gears, and rotate in opposite directions. The remaining length of a given pinion meshes with the nearer spur gear on its axle. Therefore, each pinion couples that spur gear to the other pinion, and in turn, the other spur gear, and so that when the drive shaft rotates the carrier, its relationship to the gears for the individual bicycle axles is the same equally that in a bevel-gear differential.

A spur gear differential is constructed from two identical coaxial epicyclic gear trains assembled with a single carrier such that their planet gears are engaged. This forms a planetary gear train with a fixed carrier train ratio R = -1.

In this case, the primal formula for the planetary gear train yields,

or

Thus, the angular velocity of the carrier of a spur gear differential is the average of the angular velocities of the sun and annular gears.[vii] [ page needed ]

Non-automotive applications [edit]

Differential used to control the have-upward reel of a paper tape reader made by Tally circa 1962. The bevel gears spin freely on their shafts, unless a restriction shoe stops the left gear. This causes the planet gear to drive the output shaft at one-half the speed of the driven gear on the right.

Planetary differential used to bulldoze a chart recorder circa 1961. The motors drive the sun and annular gears, while the output is taken from the planet gear carrier. This gives three unlike speeds depending on which motors are on.

Chinese south-pointing chariots may also have been very early applications of differentials. The chariot had a pointer which constantly pointed to the south, no thing how the chariot turned every bit information technology travelled. It could therefore exist used every bit a blazon of compass. Information technology is widely thought that a differential mechanism responded to any difference between the speeds of rotation of the 2 wheels of the chariot, and turned the pointer accordingly. However, the mechanism was not precise enough, and, later a few miles of travel, the dial could have very well been pointing in the completely opposite direction.

The primeval definitely verified employ of a differential was in a clock fabricated past Joseph Williamson in 1720. It employed a differential to add together the equation of fourth dimension to local hateful time, as determined past the clock machinery, to produce solar fourth dimension, which would accept been the same as the reading of a sundial. During the 18th Century, sundials were considered to testify the "correct" time, so an ordinary clock would frequently have to be readjusted, fifty-fifty if it worked perfectly, because of seasonal variations in the equation of fourth dimension. Williamson's and other equation clocks showed sundial time without needing readjustment. Nowadays, nosotros consider clocks to be "correct" and sundials usually incorrect, so many sundials carry instructions well-nigh how to utilise their readings to obtain clock fourth dimension.

In the showtime one-half of the twentieth century, mechanical analog computers, called differential analyzers, were synthetic that used differential gear trains to perform addition and subtraction. The U.S. Navy Mk.1 gun burn down control calculator used about 160 differentials of the bevel-gear type.

A differential gear train can be used to allow a difference between two input axles. Mills often used such gears to apply torque in the required axis. Differentials are also used in this way in watchmaking to link two divide regulating systems with the aim of averaging out errors. Greubel Forsey utilize a differential to link two double tourbillon systems in their Quadruple Differential Tourbillon.

Application to vehicles [edit]

Automotive differential: The drive gear 2 is mounted on the carrier 5 which supports the planetary bevel gears 4 which engage the driven bevel gears 3 attached to the axles 1.

"Effectually the Corner" (1937), a Jam Handy film made for Chevrolet explaining how an open differential works

A vehicle with two drive wheels has the problem that when it turns a corner the drive wheels must rotate at different speeds to maintain traction. The automotive differential is designed to bulldoze a pair of wheels while allowing them to rotate at dissimilar speeds. In vehicles without a differential, such as karts, both driving wheels are forced to rotate at the aforementioned speed, normally on a common axle driven by a uncomplicated chain-drive mechanism.

When cornering, the inner bicycle travels a shorter distance than the outer wheel, so without a differential either the inner wheel rotates too quickly or the outer bike rotates also slowly, which results in difficult and unpredictable handling, damage to tires and roads, and strain on (or possible failure of) the drivetrain.

Hypoid gear pair that connects an automotive drive shaft to a differential

In rear-bike drive automobiles the central drive shaft (or prop shaft) engages the differential through a hypoid gear (band and pinion). The ring gear is mounted on the carrier of the planetary chain that forms the differential. This hypoid gear is a bevel gear that changes the direction of the bulldoze rotation.

Loss of traction [edit]

I undesirable side effect of an open differential is that it can limit traction under less than ideal conditions. The amount of traction required to propel the vehicle at whatsoever given moment depends on the load at that instant—how heavy the vehicle is, how much elevate and friction in that location is, the gradient of the road, the vehicle's momentum, and and so on.

The torque applied to each driving wheel is the result of the engine, manual and drive beam applying a twisting force against the resistance of the traction at that roadwheel. In lower gears, and thus at lower speeds, and unless the load is uncommonly high, the drivetrain tin supply every bit much torque equally necessary, so the limiting gene becomes the traction under each wheel. It is therefore convenient to define traction as the amount of force that can be transmitted between the tire and the road surface earlier the wheel starts to slip. If the torque applied to ane of the drive wheels exceeds the threshold of traction, then that wheel volition spin, and thus provide torque only at the other driven cycle equal to the sliding friction at the slipping cycle. The reduced net traction may still exist enough to propel the vehicle slowly.

An open (non-locking or otherwise traction-aided) differential always supplies close to equal torque to each side. To illustrate how this can limit torque applied to the driving wheels, imagine a elementary rear-wheel drive vehicle, with ane rear roadwheel on asphalt with good grip, and the other on a patch of slippery ice. It takes very little torque to spin the side on glace ice, and because a differential splits torque equally to each side, the torque that is applied to the side that is on cobblestone is express to this amount.[8] [9]

Based on the load, gradient, etc., the vehicle requires a certain amount of torque practical to the drive wheels to move forward. Since an open up differential limits total torque applied to both drive wheels to the amount used by the lower traction wheel multiplied by 2, when i wheel is on a glace surface, the total torque applied to the driving wheels may be lower than the minimum torque required for vehicle propulsion.[10]

Agile differentials [edit]

Fully integrated agile differentials are used on the Ferrari F430, Mitsubishi Lancer Evolution, Lexus RC F and GS F, and on the rear wheels in the Acura RL. A version manufactured by ZF is besides existence offered on the B8 chassis Audi S4 and Audi A4.[11] The Volkswagen Golf GTI Mk7 in Functioning trim also has an electronically controlled front-axle transverse differential lock, also known as VAQ.[12] The 2016 Ford Focus RS has a dissimilar type of differential setup. This essentially gives each wheel its own differential. This allows Torque vectoring and can send power to any wheel that needs it.[13]

Enthusiast interest [edit]

Globe-trotting is a popular motorsport style that has its origins in the mountains of Japan. This style of driving is known for sliding a car through a corner without leaving the road surface. To easily get the car into a slide the driver tin can utilize a express-slip differential or a welded differential. A express skid differential makes the wheels of the vehicle plow at the aforementioned speed. Since the within wheel of the automobile is going a shorter distance than the exterior cycle, this causes slippage. This slippage is what makes it easier to slide the auto effectually a plow.[14]

Meet also [edit]

- Anti-lock braking system

- Brawl differential

- Equation clock

- Hermann Aron § Electricity meters

- Locking differential

- Torque vectoring

- Traction control arrangement

- Whippletree

References [edit]

- ^ a b Wright, One thousand. T. (2007). "The Antikythera Mechanism reconsidered" (PDF). Interdisciplinary Science Reviews. 32 (1): 27–43. doi:ten.1179/030801807X163670. S2CID 54663891. Retrieved twenty May 2014.

- ^ Basic Mechanisms in Fire Command Computers, Part 1, Shafts Gears Cams and Differentials, posted as 'U.Due south. Navy Vintage Fire Command Computers' (Training Movie). U.S. Navy. 1953. Upshot occurs at 37 seconds. MN-6783a. Archived from the original on 18 Nov 2021. Retrieved xx September 2021.

- ^ Presentation given to the NHRF in Athens, half-dozen March 2007 – M. T. Wright

- ^ Britannica Online

- ^ "History of the Car". Full general Motors Canada. Retrieved nine January 2011.

- ^ Preston, J.M. (1987), Aveling & Porter, Ltd. Rochester., North Kent Books, pp. xiii–14, ISBN0-948305-03-7 includes sectional drawing.

- ^ Uicker, J. J.; Pennock, Thou. R.; Shigle, J. Due east. (2003). Theory of Machines and Mechanisms (third ed.). New York: Oxford University Press. ISBN9780195155983.

- ^ Bonnick, Allan (2001). Automotive Calculator Controlled Systems. p. 22. ISBN9780750650892.

- ^ Bonnick, Allan (2008). Automotive Science and Mathematics. p. 123. ISBN9780750685221.

- ^ Chocholek, S. E. (1988). "The Evolution of a Differential for the Improvement of Traction Control".

- ^ "ZF Printing release". ZF.com . Retrieved 9 Jan 2011.

- ^ "Golf VII GTI". PistonHeads.com . Retrieved 24 June 2013.

- ^ "The 2016 Ford Focus RS Gets an Advanced Torque-Vectoring AWD Organisation". Automobile. 4 November 2015. Retrieved 21 September 2020.

- ^ Skwarczek, Matthew (29 March 2020). "What Makes a Limited-Sideslip Differential Desirable?". MotorBiscuit . Retrieved 21 September 2020.

External links [edit]

- A video of a 3D model of an open differential

- Popular Scientific discipline, May 1946, How Your Car Turns Corners, a large article with numerous illustrations on how differentials piece of work

DOWNLOAD HERE

Shafts a and B Connect the Gear Box to the Wheel Assemblies of a Tractor, and Shaft C -chegg UPDATED

Posted by: carolynscialicested.blogspot.com

0 comments:

Post a Comment